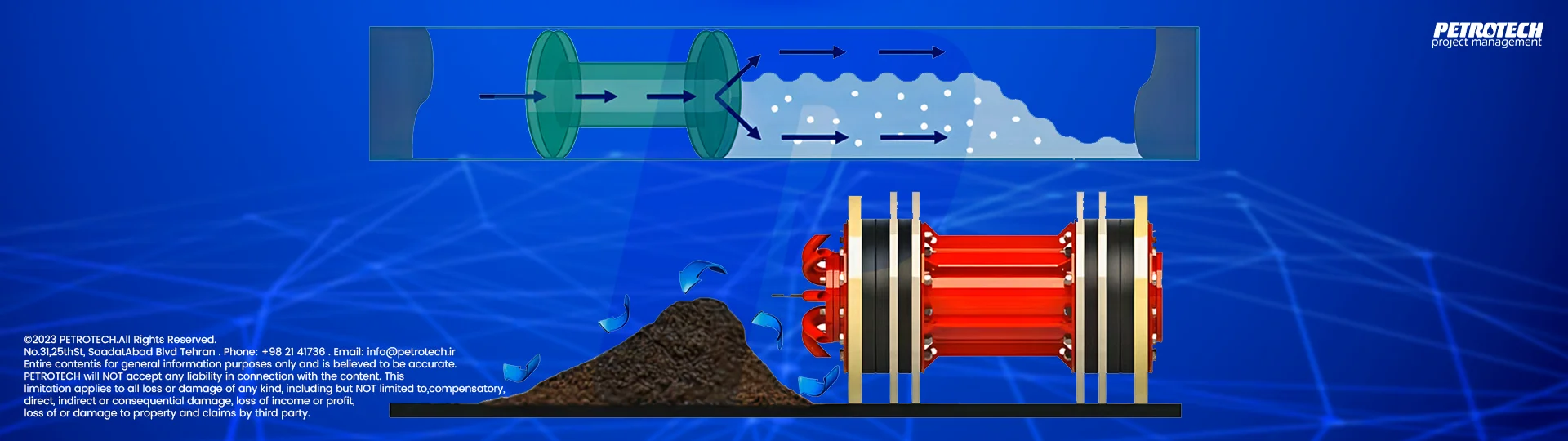

The Ultimate Clean™ series of tools provides the highest degree of flexibility for virtually all pipeline cleaning applications including general and heavy-duty cleaning, ferrous debris removal as well as gauging and batching tasks.

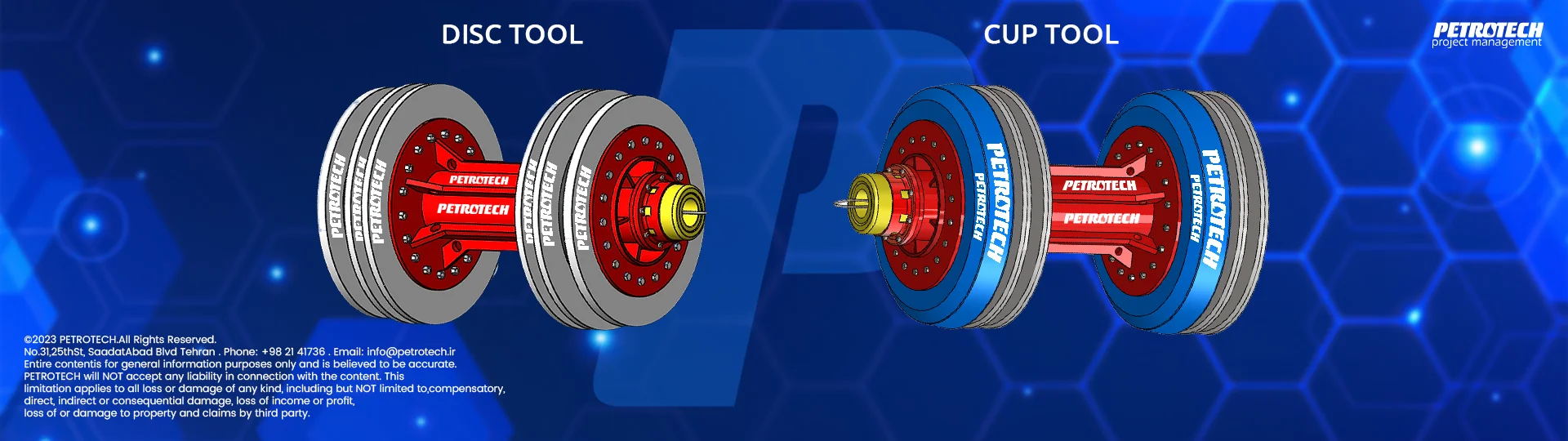

With its slender multi-bolt design, the Ultimate Clean™ pipeline cleaning tool has excellent pipe passage properties. This series provides the highest degree of flexibility for virtually all applications such as general and heavy-duty cleaning, ferrous debris removal as well as gauging and batching tasks. Operating life is maximized through the use of highly wear resistant Plasthan® polyurethane (PU) materials. Ultimate Clean™ tools can optionally be supplied in accordance with ATE X directive 94/9/EC. PETROTECH pipeline cleaning tools are designed, engineered and manufactured in-house.

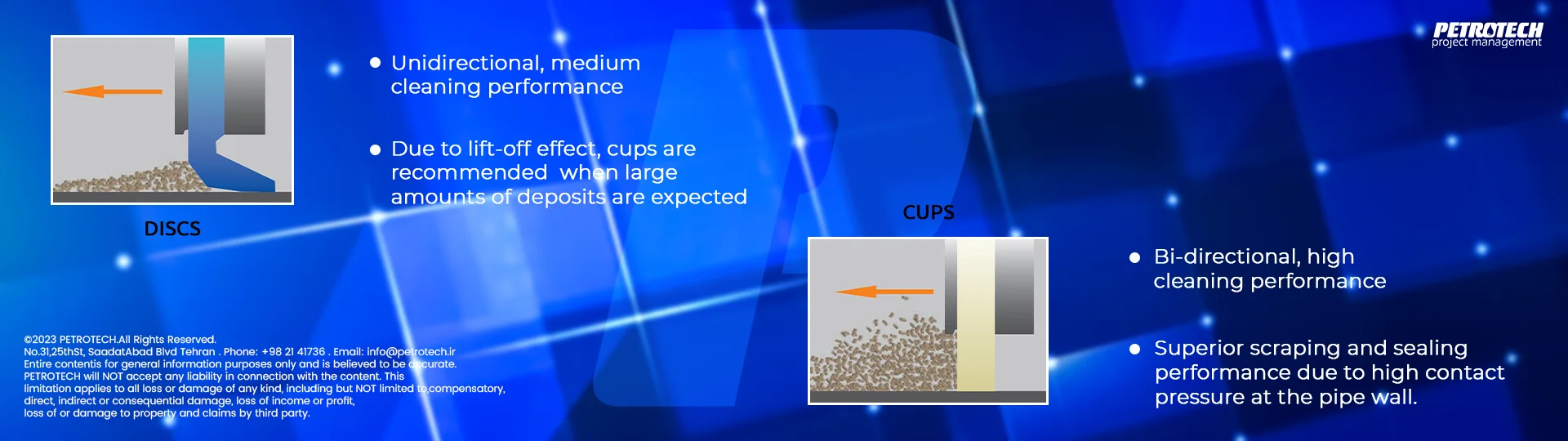

Depending on the pipeline’s condition and the objective of the cleaning run, Ultimate Clean™ tools can be equipped with combinations of different accessories:

Grit-blasted carbon steel, coated with primer and epoxy. Flanges chamfered to avoid sharp edges, designed to withstand extreme differential pressures.

(Standard version: 2 discs, long-run version: 4 discs) Made of Plasthan® 1200, hardness 85 Shore A

One plastic bumper mounted to the front in order to protect the tool against impact; BIDI operation possible.

(Standard and long-run version: 4 discs) Made of Plasthan® 1100, hardness 65 Shore A

(Standard version: 2 cups, long-run version: 4 cups) Made of Plasthan® 1200, hardness 85 Shore A

Metric bolting grade 8.8, zinc-plated. Metallic self-locking nuts according to DIN 980 V.

In many pipeline applications, a customized disc tool design will result in significantly improved performance. Incorporating a range of customization options, the Ultimate Clean™ tool can be adjusted to suit the geometry requirements of specific pipeline systems, thereby allowing safe passage of valves and fittings.

Featuring high-temperature Plasthan® grades for hot media (temperature range 100°C and above)

With special Plasthan® 1306 disc/cup materials

For highly aggressive, corrosive media, combined with high temperature requirements

Diameter configurations for pipelines with two or more different nominal sizes (multi-diameter pipelines)

Special cups with tungsten carbide studs for removal of severely encrusted debris such as scale and hard wax

EXCELLENCE THROUGH EXPERIENCE

At PETROTECH, we offer a wide range of products and services to help global oil and gas operators ensure the safety, longevity, and performance of their assets. Customers rely on our technology, expertise, and experience, as well as our commitment to inspection, data quality, and integrity management. They trust our skilled team to tackle even the most complex projects safely.

Our goal is to prepare the pipeline industry for future fuels like hydrogen, carbon dioxide, and ammonia. We offer a roadmap with practical processes for integrating these energy sources into the grid, ensuring operators have innovative and sustainable solutions. With our extensive experience in transporting various media, we provide expertise in assessing pipeline integrity for the benefit of your grid.

Our customers in the process industry understand the crucial importance of plant safety and efficiency. That's why they turn to PETROTECH to optimize the integrity and availability of their critical assets, such as storage tanks, piping, and pressure vessels. Additionally, our innovative retrofit-ready PETROTECH EMAT Flowmeter offers precise and stable flow measurement for liquid, gas, steam, and multiphase applications, even in challenging conditions.

We have extended our pipeline inspection expertise to the steel mill, integrating inspection systems into the manufacturing process to assess hot steel plates and pipes as they are produced.

PETROTECH’s ethos is ensuring the highest levels of equipment availability this should translate to maximised return on investment for our customer assets. We achieve this by having localised service teams in each country we operate and local stores of genuine original equipment manufacturer (OEM) approved parts. Our teams are trained to the highest standards and we offer training programmes for our customers and staff.

All rights of this website are reserved and belong to Petrotech Company.