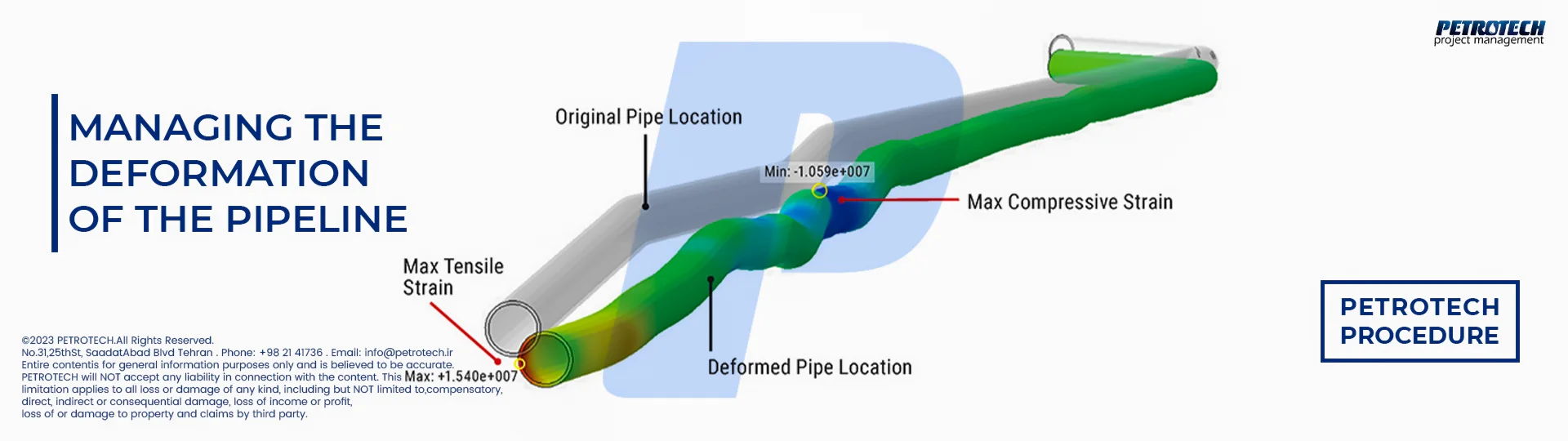

The safety and long-term performance of a pipeline can be compromised significantly by geometrical damage such as dents, wrinkles, bulges, ovalization, and roof topping. Manufacturing, construction, or external factors during operation such as accidental third-party damage or external loading cause geometric damage.

Deformation can threaten pipeline integrity, particularly when it is combined with other anomalies like gouges, corrosion, or weld flaws.

In fact, damage due to external interference remains one of the main causes of pipeline failures globally. Deformation features such as wrinkles or buckles may be associated with areas of high bending strain and pipeline movement, which can be identified with pipeline mapping systems. Severe pipeline deformation can also result in flow restrictions or prevent the passage of pipeline cleaning and inspection tools.

Therefore, having a reliable pipeline deformation management strategy that covers the identification, sizing, assessment, and repair of geometric damage is critical for all pipeline operators.

The most effective way to assess changes in shape is to approach deformation management. The PETROTECH Group believes that the best way to do this is by tackling the challenge from all angles; combining the most advanced pipeline deformation inspection solutions, the knowledge of subject-matter experts, and industry best practices give operators the information they need to make the best possible integrity management decisions. PETROTECH supports operators beyond short-term decision-making and provides management plans and training to enable them to take the right maintenance actions at the right time in order to extend the life, safety, and performance of their pipelines.

Knowing the exact position of pipelines is a key part of many pipeline integrity management activities from aligning multiple data sets to repair planning. PETROTECH supports pipeline operators with a high-resolution pipeline mapping service that provides accurate information about the pipeline centerline. In addition, deformation features such as wrinkles or buckles may be associated with areas of high bending strain and pipeline movement.

The integrity of pipelines threatens by Cracks. And pipeline cracks are not all the same. A variety of crack types such as fatigue cracks and environmental cracking as well as crack locations – including in the pipe body and the complex geometry of girth welds and seam welds – all pose risks to a pipeline’s efficiency and safety.

PETROTECH’s Pipeline Integrity Framework for Cracking encourages a holistic approach to pipeline cracking. Our Inspection services identify a wide variety of crack formations with a very small physical footprint. They also find crack-like features such as manufacturing flaws.

The framework would not be complete without our integrity team, which has unrivaled experience in identifying likely flaws, selecting crack inspection system combinations, interpreting in-line inspection data, providing assessments, and managing threats.

Pipelines have unique characteristics. Approaching crack detection and assessment for pipelines is the most effective way to take control of cracks. The PETROTECH Group has created a Pipeline Integrity Framework for Cracking that is a consolidation of current industry best practices and the most advanced pipeline crack inspection solutions with the knowledge of subject-matter experts. It outlines all the key elements needed to develop a comprehensive and justifiable crack assessment and mitigation program. It is a systematic approach effective in addressing even the most challenging forms of cracking.

This approach does not rely on the most sophisticated technology alone, as it will also fall short if not seamlessly integrated into a robust management framework. Instead, it suggests an added-value approach to ensure the objectives and needs are understood. Only then can the full capacity of the crack inspection technology be utilized. It includes pre-inspection elements that answer critical questions to allow for optimal system selection. The framework continues to guide the entire process from inspection to integrity, ultimately resulting in a proper threat management plan. It is modular, allowing operators to choose which elements are relevant to them in reaching their objectives and making the decisions needed for safe and efficient pipeline operation. In-house subject matter experts are available to discuss crack assessment directly with operators – ensuring the best solution is found for every unique asset.

For many pipelines built before the widespread use of GPS satellites, construction survey records are inaccurate or have even been lost, so the pipeline position is not accurately known. However, to react quickly to critical pipeline defects, exact information on the position of a pipeline is required to ensure that the right location is excavated. Knowing the depth of cover at every location will also help with excavation planning and ensure protection from third-party damage.

In addition, geohazards such as landslides, seismic events, high rainfall, and erosion can lead to pipeline movement and high associated strain values. Information on the degree of bending experienced by a pipeline and how much it is affected by strain is vital for safe operation. In addition, understanding and managing geohazards require a clear understanding of the transitions between stable and moving ground.

No matter whether construction survey records are inaccurate have been lost, or the pipeline has moved from its original position, knowing the exact position of pipelines is key for a safe and cost-efficient operation. Consequently, reliable information on the position of features in a pipeline, the position of the pipeline, and changes in curvature are of great importance to all pipeline operators.

PETROTECH supports them with a high-resolution pipeline mapping service that provides accurate information about the pipeline route and areas of bending and how to manage associated threats in the most effective and cost-efficient way.

According to the unpredictability of environmental movements, each pipeline mapping endeavor is unique. The most effective way to assess changes in shape and movement is to approach pipeline mapping comprehensively. The PETROTECH Group joins current industry best practices and the most advanced pipeline mapping inspection solutions with the knowledge of subject-matter experts to enable pipeline operators to make the best possible integrity management decisions. PETROTECH supports operators beyond short-term decisions and provides management plans and training to enable them to take the right maintenance actions at the right time to extend the life, safety, and performance of their pipelines.

Pipelines are exposed to a wide range of potential damage mechanisms, which may eventually result in leakage or worse if not identified and mitigated at the right time. While single threats may severely compromise the operational safety of a given pipeline, combined threats like corrosion in dents, or cracks in corrosion pose an even higher risk to the asset’s overall integrity.

PETROTECH offers a variety of modular inspection technologies that can be merged into one tool to comprehensively assess various types of threats in one ILI run, ultimately reducing inspection-related costs and efforts. Each technology is strong on its own. However, the combination of multiple technologies provides significant added value as the combined evaluation of various data sets leads to more accurate integrity assessments.

With our well-structured and certified process, our analysts provide the required high-quality reports on time. Multiple inspection data is input for our combined data analysis using synergy effects of the independent and complementary nature of the measurements.

Our reporting and data management software ensures easy data visualization and facilitates a versatile use of inspection results.

Corrosion is a particularly significant threat, which, if not detected, monitored and mitigated, creates irreparable damage. Corrosion can be introduced in many ways and at any point in a pipeline’s lifecycle, creating a constant need for detection and monitoring. In addition, corrosion does not discriminate, it flourishes in a wide variety of environments. Be it general wall thinning, pitting corrosion or stress corrosion, all types of pipeline corrosion have one thing in common. they reduce a pipeline’s safety and efficiency and therefore must be kept in check at all times.

PETROTECH pursues a holistic approach to pipeline corrosion management that goes far beyond mere inspection. The highly innovative metal loss detection systems in the industry, combined with second-to-none engineering consultancy and data management competence, provide operators with full support in managing the risk presented by the overwhelming threat of pipeline corrosion.

We are convinced that a big-picture mindset is the most effective way to efficiently preserve integrity. The PETROTECH Group has therefore adopted an integrated framework approach for pipeline integrity management. This approach adapts not only to each type of threat but also to each individual pipeline and operator. It consolidates industry best practices and the most advanced inspection solutions, together with the knowledge of a multi-disciplinary team of subject matter experts. It is a systematic approach effective in managing even the most challenging forms of metal loss, ensuring a close integrity management partnership where everybody understands the objectives and their role.

EXCELLENCE THROUGH EXPERIENCE

At PETROTECH, we offer a wide range of products and services to help global oil and gas operators ensure the safety, longevity, and performance of their assets. Customers rely on our technology, expertise, and experience, as well as our commitment to inspection, data quality, and integrity management. They trust our skilled team to tackle even the most complex projects safely.

Our goal is to prepare the pipeline industry for future fuels like hydrogen, carbon dioxide, and ammonia. We offer a roadmap with practical processes for integrating these energy sources into the grid, ensuring operators have innovative and sustainable solutions. With our extensive experience in transporting various media, we provide expertise in assessing pipeline integrity for the benefit of your grid.

Our customers in the process industry understand the crucial importance of plant safety and efficiency. That's why they turn to PETROTECH to optimize the integrity and availability of their critical assets, such as storage tanks, piping, and pressure vessels. Additionally, our innovative retrofit-ready PETROTECH EMAT Flowmeter offers precise and stable flow measurement for liquid, gas, steam, and multiphase applications, even in challenging conditions.

We have extended our pipeline inspection expertise to the steel mill, integrating inspection systems into the manufacturing process to assess hot steel plates and pipes as they are produced.

PETROTECH’s ethos is ensuring the highest levels of equipment availability this should translate to maximised return on investment for our customer assets. We achieve this by having localised service teams in each country we operate and local stores of genuine original equipment manufacturer (OEM) approved parts. Our teams are trained to the highest standards and we offer training programmes for our customers and staff.

All rights of this website are reserved and belong to Petrotech Company.