Cleaning is a vital aspect of the integrity management of pipelines and pipeline networks and is necessary at every stage throughout their lifecycle. Failure to clean your pipeline at regular intervals leads to reduced efficiency and may result in damages that impact its lifecycle. The PETROTECH Company offers a broad spectrum of pipeline cleaning solutions built on more than three decades of experience – experience gained working together with our customers on countless pipeline projects. Continuous development and innovation ensure that our cleaning solutions are backed by robust service products and experienced service personnel, providing tangible added value for our customers. We recognize that each pipeline is unique and that cleaning needs vary depending its operational purpose and lifecycle stage.

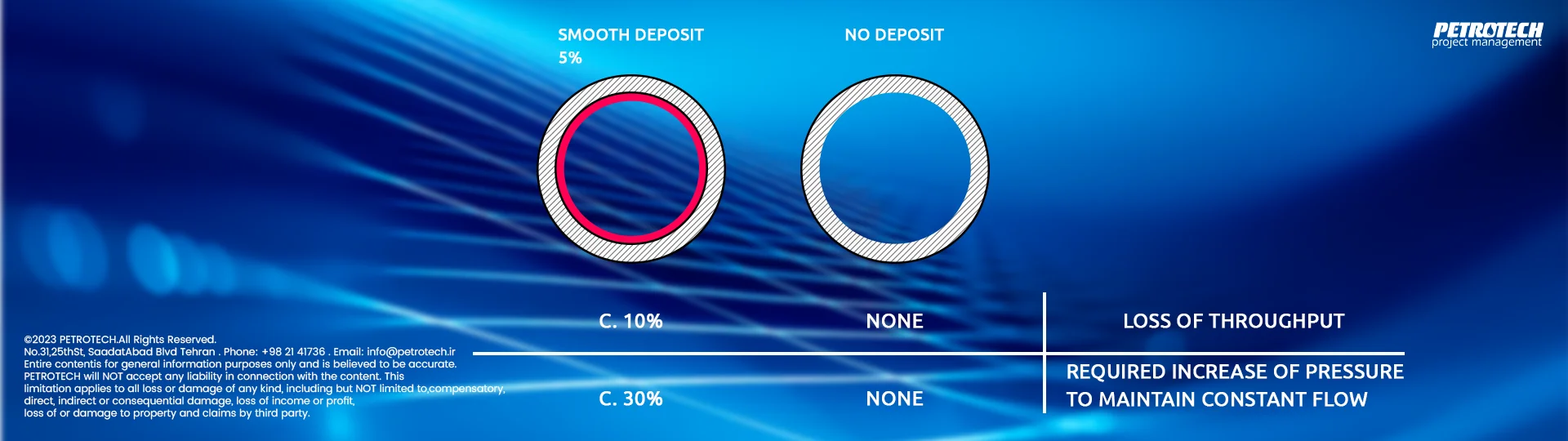

Efficient pipeline operation is dependent on two fundamental aspects: continuous transportation of the medium and maintenance of the internal diameter to ensure optimal flow of the medium. There are several factors that can seriously impact the efficiency of a pipeline, including:

Failing to clean your pipeline can dramatically affect the efficiency, safety, and reliability of the entire network. Foreign matter and buildup can damage the integrity of a pipeline, encourage the formation of corrosion and pipe thinning, and will almost certainly reduce throughput.

We aim to combat the challenges of pipeline cleanliness by offering a wide variety of predefined solutions as well as individually tailored approaches backed by an extensive portfolio and substantial experience. The cleaning requirements for a pipeline during its lifecycle are many and varied depending upon the pipeline’s lifecycle stage.

With its considerable in-house expertise in sensor and data-acquisition technologies and corrosion consultancy, the PETROTECH Company is your first choice for intelligent cleaning solutions. We use high quality electronic measurement instruments, data analysis software, and integrity management systems. Backed by over six technology and research centers worldwide, the PETROTECH Company is able to create and provide expert, customized cleaning solutions for our customers. With the support of our operating units around the globe, we help you maintain your pipelines, increase operational performance, and extend the operational lifecycle of your valuable assets.

During the pipeline manufacturing process, oils, greases, protective coatings and mill scale can contaminate pipe wall surfaces. Failure to remove this material before the pipeline is put into service can lead to considerable product contamination upon initial start-up of the pipeline. PETROTECH delivers expert cleaning services essential to avoid potential upsets.

Once installed, pipelines are often filled with water for flooding and hydro testing. This requires cleaning tools for filling and dewatering activities. In addition, special wet buckle contingency cleaning programs and support services are often required. PETROTECH’s in-house polyurethane material is renowned for providing ideal properties for efficient cleaning services.

Once in service, deposits can begin to settle on the pipe wall. If cleaning is not performed on a regular basis during production operations, these deposits can build up, encouraging corrosion growth and potentially preventing inhibitors that can protect the system from being properly applied. In addition, cleaning at this stage prepares the pipeline for further inline inspection services.

Liquids (crude oil, water, refined product, etc.) all have different characteristics and effects on the pipe wall. When a pipeline is scheduled to undergo a product change, a strict cleaning program must be executed to avoid any product contamination.

Whenever a pipeline is to be taken out of service (temporarily or permanently), cleaning and servicing of the line is vital in order to maintain the integrity of the asset during the dormant period.

Proper cleaning is also required at the end of a pipeline’s lifecycle before the asset is abandoned, recovered or reused. Utilizing some of the best cleaning solutions and tools, our decommissioning cleaning services ensure that the pipeline is thoroughly cleaned and that no pollutants are released in the process.

The PETROTECH Company has provided reliable cleaning solutions to pipeline operators throughout the world for more than 20 years. Partnering with PETROTECH and working closely with our experienced personnel to execute successful cleaning programs will help you achieve your objectives by:

Implementing proactive integrity management and an adequate cleaning program translates into cost optimization, thus enabling you to retain control of your maintenance budget. This is one of the ways we create ultimate value for our customers, and another reason why PETROTECH is the most reliable, competitive and flexible solutions provider – a partner you can trust.

Routine maintenance programs are crucial in the lifecycle extension of any system. Pipelines are no exception. Many of our cleaning solutions are designed to fulfill regular maintenance requirements and to provide pre-inspection cleaning support. As part of our maintenance service we:

Cup and disc tools can be fitted with an array of cleaning support elements, including but not limited to brushes, magnets, descaling and dewaxing equipment, as well as geometric gauging plates and bend detection technologies.

Furthermore, all tools can be equipped with PETROTECH -developed instrumentation including transmitters for tracking or pipeline data loggers to record operational data and cleaning effectiveness. ATEX/Ex compliant tools are commonplace in PETROTECH’s portfolio of electronic instruments.

No two pipelines are the same. There are many challenges when cleaning a pipeline that can render a standard approach impractical or even unfeasible. With comprehensive experience gained from a variety of challenging cases over the years, our advanced solutions go beyond maintenance cleaning and tackle special requirements of the project in questions.

PETROTECH’s engineers design suitable high-performance solutions considering:

From pre-commissioning cleaning of new pipelines to hydrocarbon removal solutions for pipelines being de-commissioned, or for those special projects where a tailor-made tool is required, PETROTECH has the knowledge, expertise and in-house capability to deliver a solution that addresses every aspect of the challenge.

Examples include, but are not limited to, design adjustments for subsea launching and recovery purposes, provision of high performance tracking technologies, incorporation of housings for onboard tracking equipment, latching systems, pressure bypass systems, speed control measures and many more.

Our Clean suite for advanced applications includes Clean Active. This all-inclusive service line includes solutions for black powder removal, controlled liquids removal, and the provision of speed and bypass controlled cleaning solutions. Additionally we provide dual and multi-diameter line cleaning technologies as well as SMART (Pipeline Condition Monitoring) cleaning solutions.

In order to deliver a truly comprehensive portfolio, PETROTECH offers desktop feasibility studies as well as testing, and also provides training support for field cleaning operations. Additionally, PETROTECH is experienced in providing a range of corrosion consultancy and flow assurance related services.

Uncertainty is something to be avoided when dealing with the safety and efficiency of a critical pipeline asset. Feasibility studies provide the opportunity to minimize risk. For example, in the case of a challenging pipeline cleaning project requiring the development.

As an additional step in creating confidence, PETROTECH can offer pull and/or pump tests. These tests can verify the passage of cleaning tools in pipelines that contain several challenging features. Testing can also validate any special requirements such as tracking systems and data recording in authentic environmental conditions.

Our engineering support extends to operational project management on turn key projects requiring ancillary support services – managing everything from initiation – through planning and design, execution, monitoring, controlling and post remediation follow up (e.g. in-field verification) works.

Our integrity management support – incorporating our corrosion consultancy services – includes, auditing and inspection, corrosion monitoring, modeling and mitigation support services in addition to remnant life prediction and evaluation and strategy management.

EXCELLENCE THROUGH EXPERIENCE

At PETROTECH, we offer a wide range of products and services to help global oil and gas operators ensure the safety, longevity, and performance of their assets. Customers rely on our technology, expertise, and experience, as well as our commitment to inspection, data quality, and integrity management. They trust our skilled team to tackle even the most complex projects safely.

Our goal is to prepare the pipeline industry for future fuels like hydrogen, carbon dioxide, and ammonia. We offer a roadmap with practical processes for integrating these energy sources into the grid, ensuring operators have innovative and sustainable solutions. With our extensive experience in transporting various media, we provide expertise in assessing pipeline integrity for the benefit of your grid.

Our customers in the process industry understand the crucial importance of plant safety and efficiency. That's why they turn to PETROTECH to optimize the integrity and availability of their critical assets, such as storage tanks, piping, and pressure vessels. Additionally, our innovative retrofit-ready PETROTECH EMAT Flowmeter offers precise and stable flow measurement for liquid, gas, steam, and multiphase applications, even in challenging conditions.

We have extended our pipeline inspection expertise to the steel mill, integrating inspection systems into the manufacturing process to assess hot steel plates and pipes as they are produced.

PETROTECH’s ethos is ensuring the highest levels of equipment availability this should translate to maximised return on investment for our customer assets. We achieve this by having localised service teams in each country we operate and local stores of genuine original equipment manufacturer (OEM) approved parts. Our teams are trained to the highest standards and we offer training programmes for our customers and staff.

All rights of this website are reserved and belong to Petrotech Company.