Mounted on any in-line inspection or cleaning tool, the PDL can measure and record temperature profiles, detect and locate restrictions and deposits, monitor tool behavior, assess cleaning progress and effectiveness, and verify operational pipeline conditions – all while the run is performed.

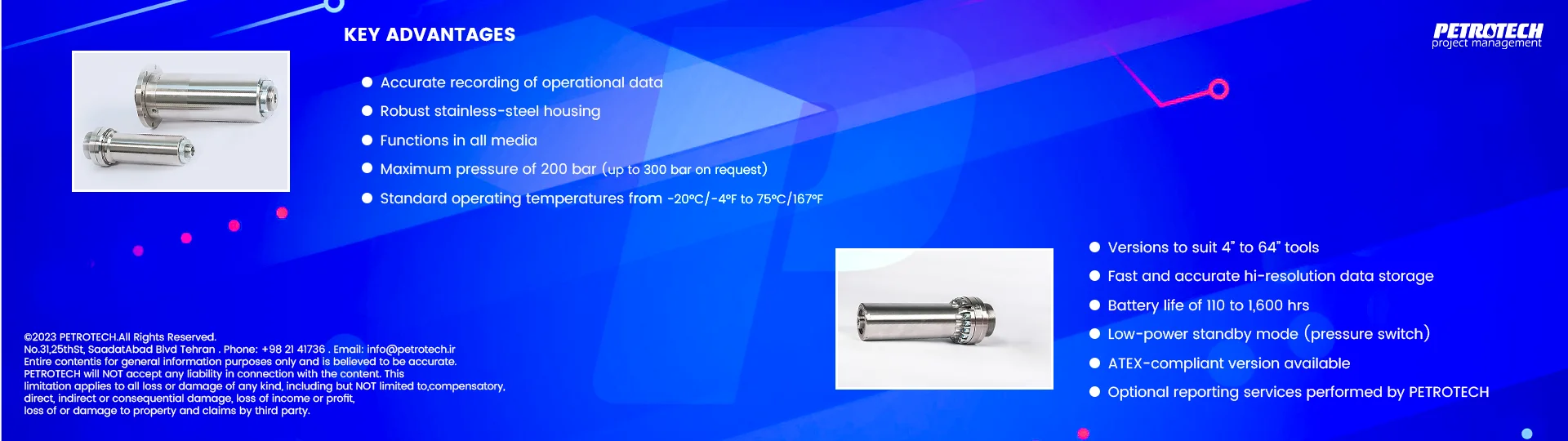

PETROTECH’s Pipeline Data Loggers (PDL4, PDL14 and ATEX PDL) are designed to collect and store operational data during a pipeline inspection. They provide operators with detailed time-dependent data, such as temperature of the medium, pressure conditions in the pipeline, differential pressure and accelerations.

The PDL is designed as a stand-alone unit, which can be added to any pipeline cleaning or inspection tool from 4” to 64”. All versions comprise angular rotation sensors, allowing indication of bends including bend angle (velocity-dependent). The user-friendly software makes it easy to configure and read out the stored data. All data can be analyzed based on various criteria and visualized with PETROTECH software.

By analyzing the data, it is possible to use recorded temperature profiles for flow assurance modelling and to detect and locate restrictions and deposits, monitor tool behavior, assess cleaning progress and effectiveness, and verify pipeline conditions.

The supplied software allows tiled displays of the selected measurement channels. It is an intelligent platform designed to select and synchronize time frames of particular interest. PETROTECH offers a full-service option that includes data acquisition and reporting of your survey results.

The PDL can be attached to any standard cleaning tool and employs fast-response, low-current sensors that can record for more than 80 days and up to 1,600 km (1,000 mi) of inspection. Data is presented in an easy-to-understand graphical format using the supplied software.

EXCELLENCE THROUGH EXPERIENCE

At PETROTECH, we offer a wide range of products and services to help global oil and gas operators ensure the safety, longevity, and performance of their assets. Customers rely on our technology, expertise, and experience, as well as our commitment to inspection, data quality, and integrity management. They trust our skilled team to tackle even the most complex projects safely.

Our goal is to prepare the pipeline industry for future fuels like hydrogen, carbon dioxide, and ammonia. We offer a roadmap with practical processes for integrating these energy sources into the grid, ensuring operators have innovative and sustainable solutions. With our extensive experience in transporting various media, we provide expertise in assessing pipeline integrity for the benefit of your grid.

Our customers in the process industry understand the crucial importance of plant safety and efficiency. That's why they turn to PETROTECH to optimize the integrity and availability of their critical assets, such as storage tanks, piping, and pressure vessels. Additionally, our innovative retrofit-ready PETROTECH EMAT Flowmeter offers precise and stable flow measurement for liquid, gas, steam, and multiphase applications, even in challenging conditions.

We have extended our pipeline inspection expertise to the steel mill, integrating inspection systems into the manufacturing process to assess hot steel plates and pipes as they are produced.

PETROTECH’s ethos is ensuring the highest levels of equipment availability this should translate to maximised return on investment for our customer assets. We achieve this by having localised service teams in each country we operate and local stores of genuine original equipment manufacturer (OEM) approved parts. Our teams are trained to the highest standards and we offer training programmes for our customers and staff.

All rights of this website are reserved and belong to Petrotech Company.